Jonathan Radetz presents demountable furniture system combining natural fibres and metal structure in project funded by German government

German designer Jonathan Radetz has developed an innovative convertible furniture system that combines renewable flax fabric with infinitely recyclable steel tubes. The LinumTube project, resulting from a partnership between Studio Jonathan Radetz and research institute Fraunhofer WKI, was presented during Dutch Design Week in Eindhoven.

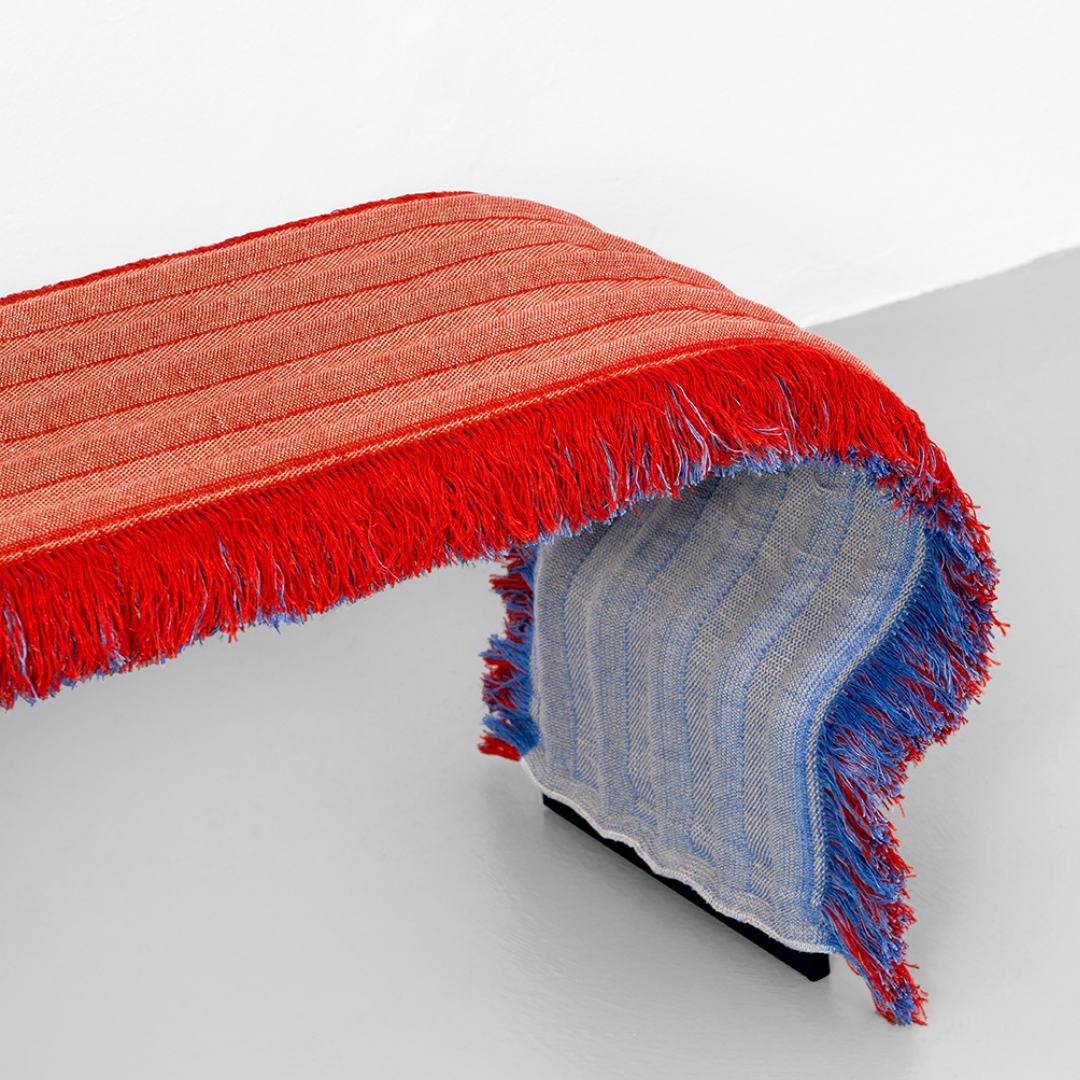

Photo: Tamara Eda Temuçin

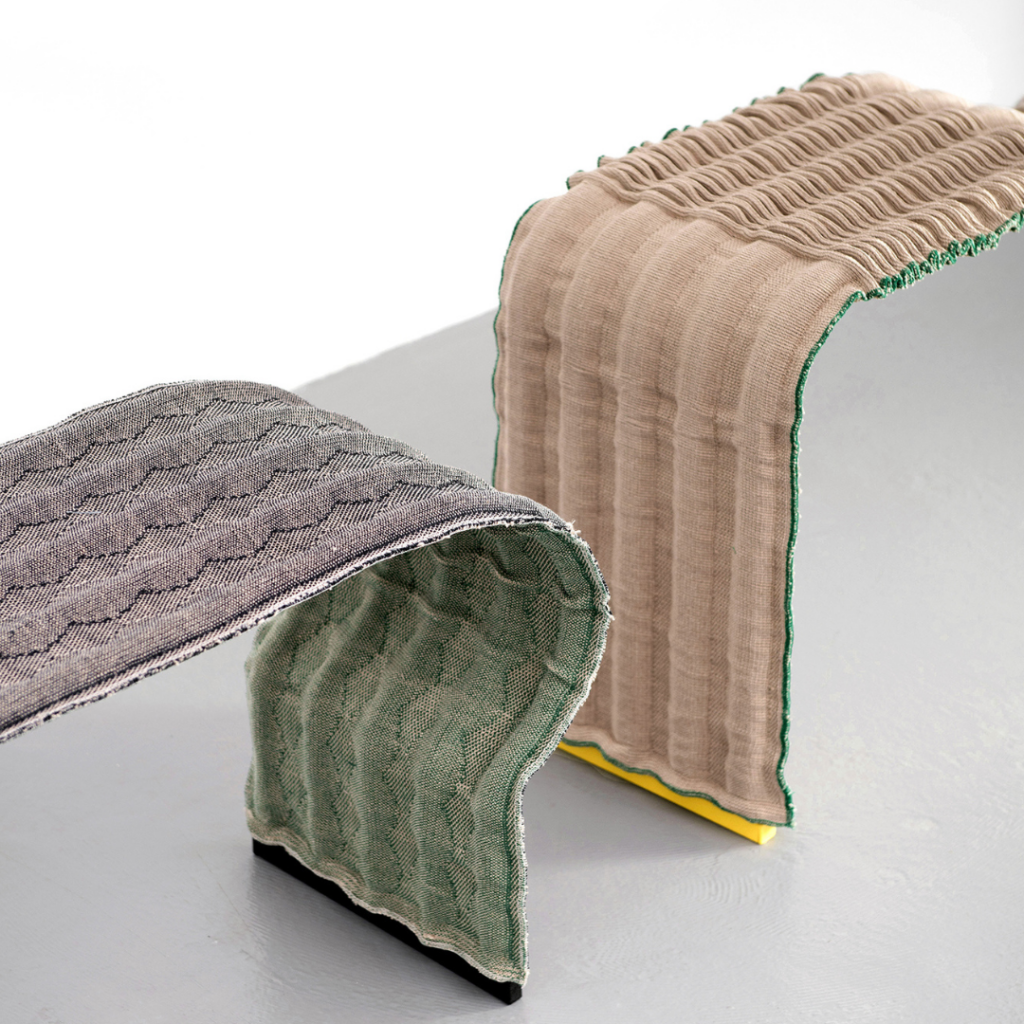

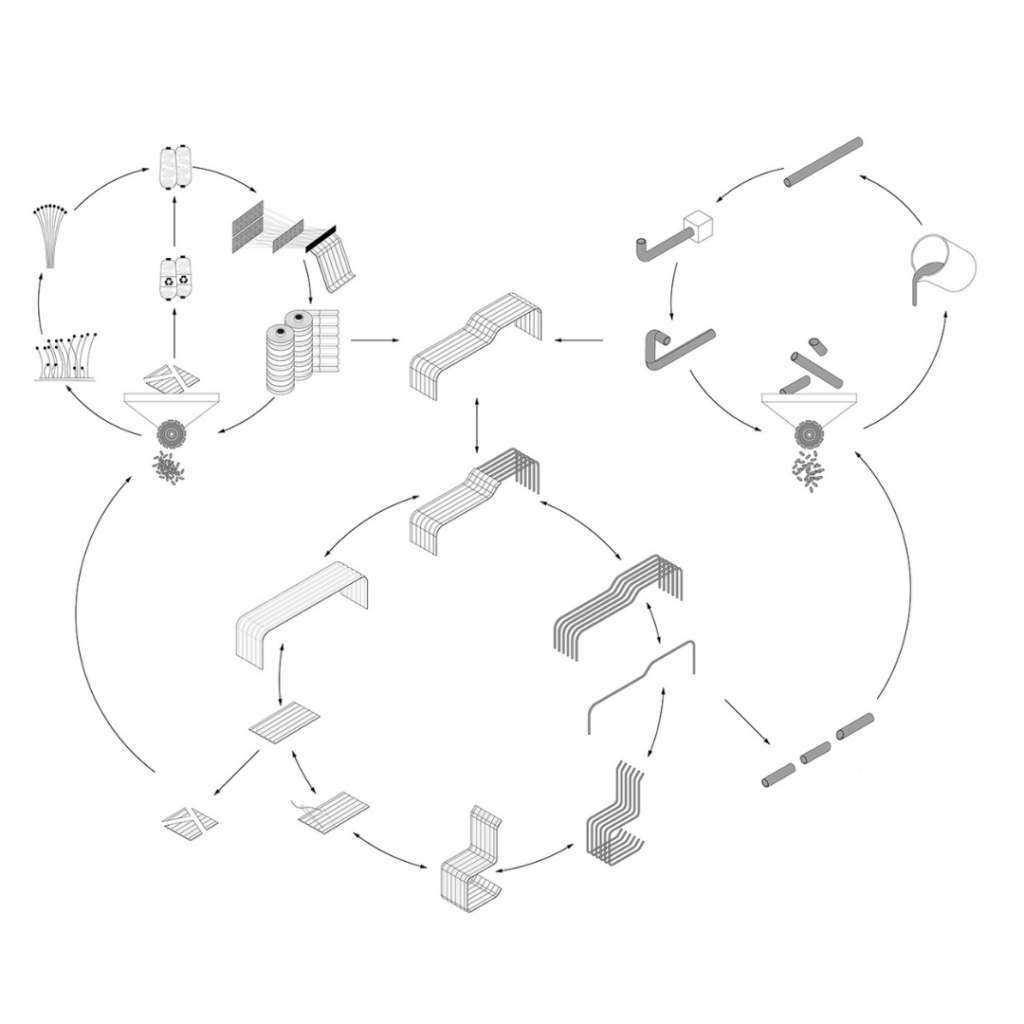

The furniture’s main characteristic is the possibility of complete disassembly without tools. All components can be separated, facilitating transport, reuse and recycling. “The visible separability makes circular principles tangible”, project materials explain.

The production process uses a special weaving technique that creates multi-layered fabrics with integrated tunnels for steel tubes, all on the same loom. This minimises additional processing stages and reduces waste. The combination of flax fabric and thin metal tubes results in a lightweight yet stable structure.

Professional background

Born in 1985, Radetz trained as a cabinet maker and product designer. His career includes positions at modern design brand e15 and in the studios of both Stefan Diez and Saskia Diez Jewellery. The designer works in Frankfurt, in the Sachsenhausen district, known for its museums and cultural scene.

Radetz’s design philosophy is characterised by a fascination with timeless modern forms. His work ranges from furniture to accessories and jewellery. “Fashion, architecture, furniture, nature and people become his creative impulses”, studio presentation materials describe.

The designer works with an interdisciplinary team of designers and production partners. His method consists of breaking down each idea into its essential components, working playfully yet consistently with materials and forms.

Circular economy

The LinumTube project receives funding from the German Federal Ministry of Research, Technology and Space. According to the developers, virtually no production waste occurs, and residual materials return to the production cycle.

Beyond technical efficiency, the project seeks to promote socio-ecological transformation. Users can reupholster or convert the furniture to another geometry themselves, which strengthens resource awareness and encourages participatory design.

The use of natural fabric emphasises material origin, whilst the visible joining system educates about circular economy principles. The furniture’s durability and adaptability are central characteristics of the project.

Photos: Tamara Eda Temuçin